What we do

Contact information:

Highlights

Fast, reliable acoustic underwater data transfer for naval operations

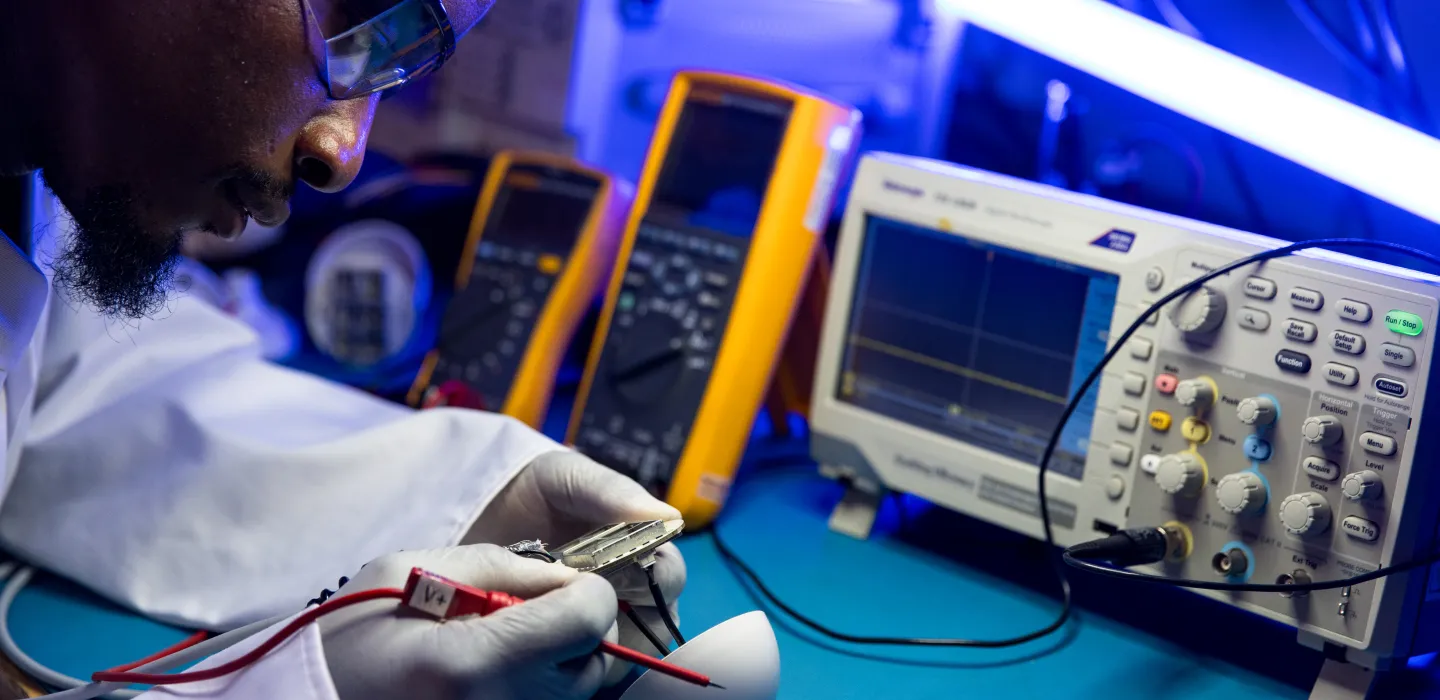

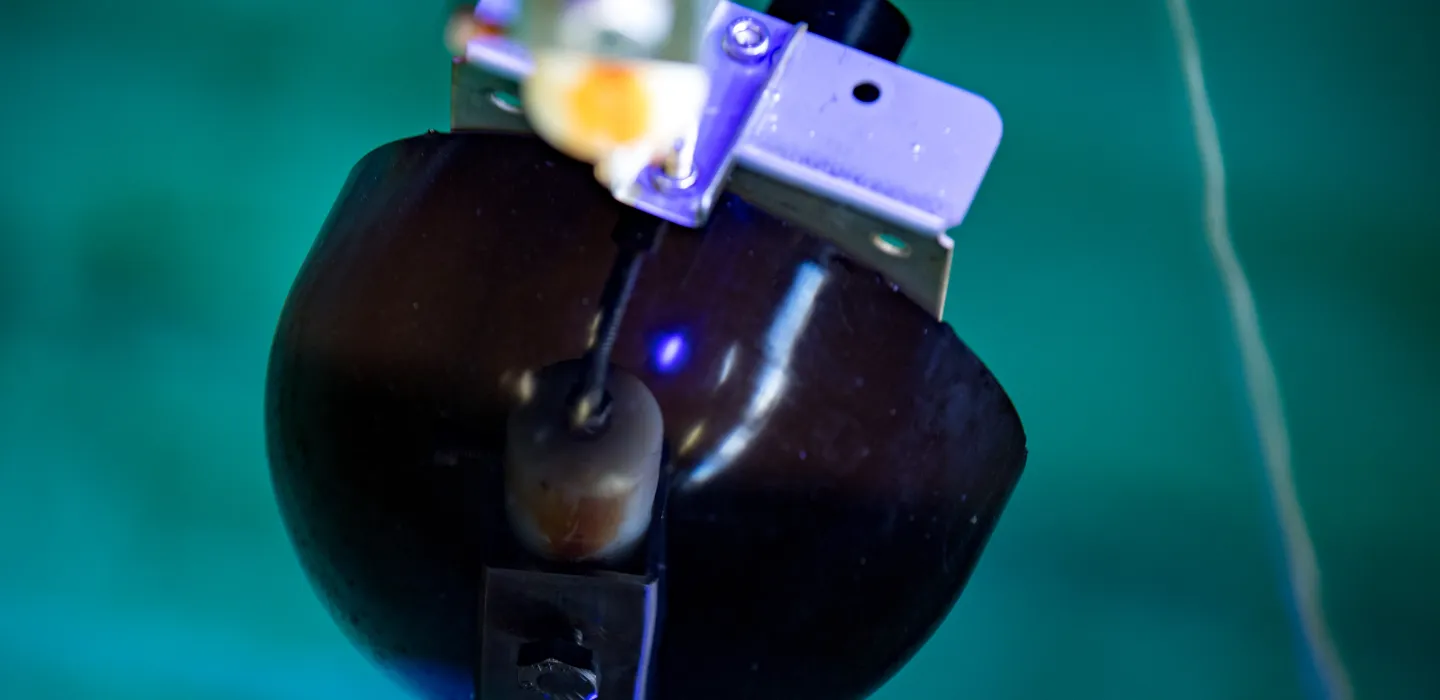

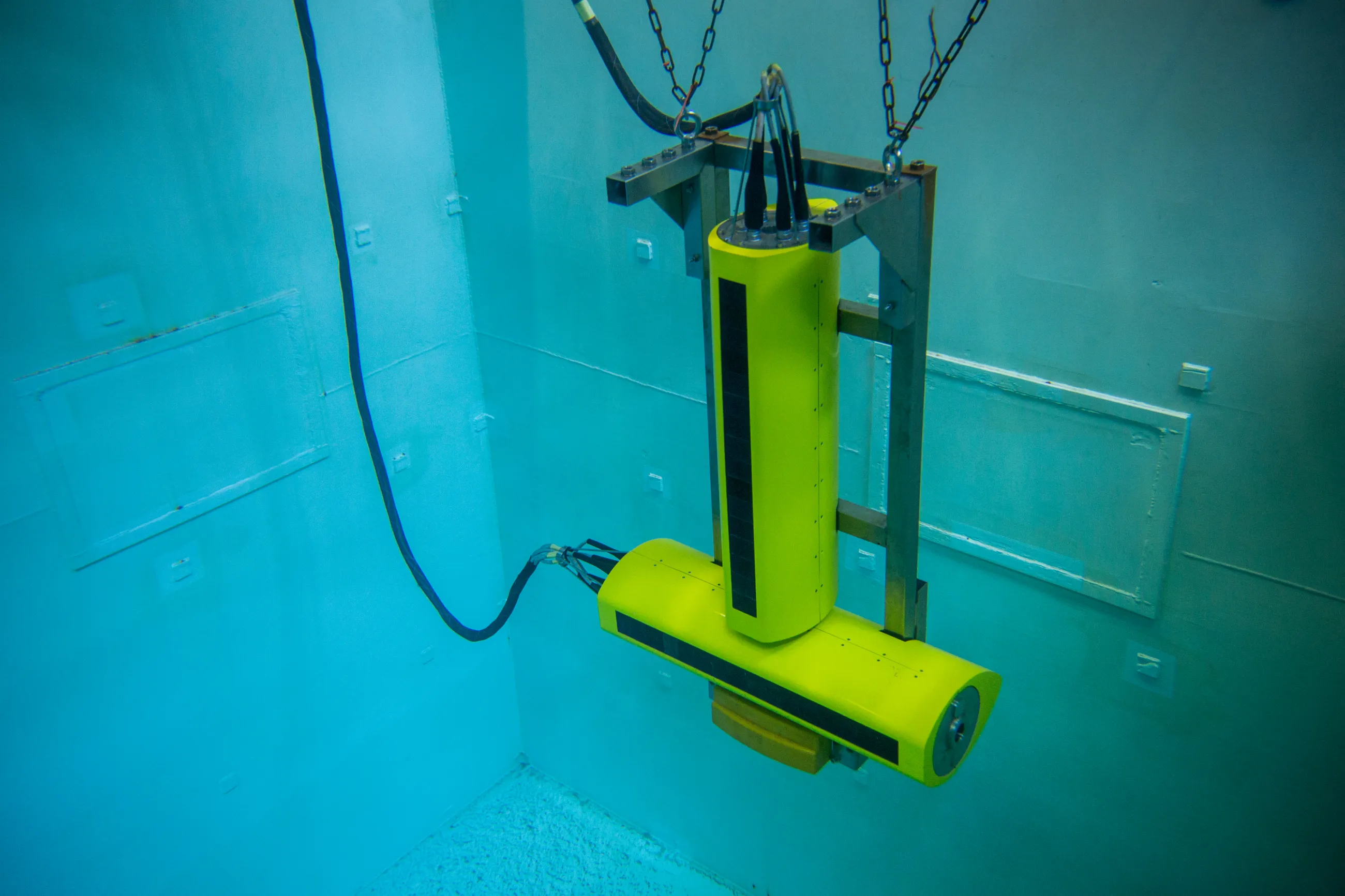

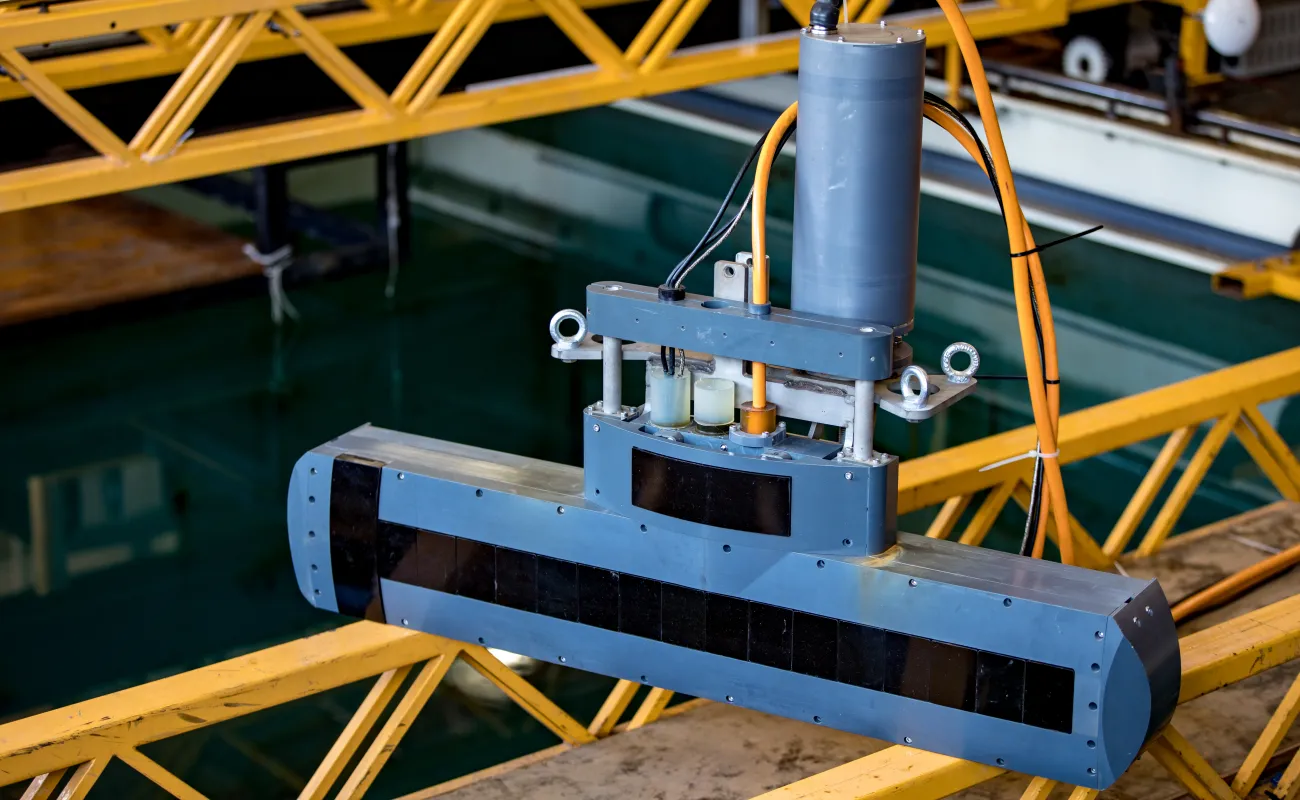

The CSIR achieved near-perfect transmission and data rates exceeding 240 kbps during a demonstration of the latest version of its broadband underwater data communication system for a defence client at its underwater acoustic testing facility. Ongoing research focuses on developing fast and reliable underwater acoustic data transmission to enable the transfer of data – such as sonar images – over distances of up to 500 m. This technology is designed to enhance the operational capabilities of the South African Navy.

Our research

Our facilities