What we do

Contact information:

Highlights

New infrastructure for health and related industries

The CSIR has established a state-of-the-art facility to support South Africa’s health and related industries. Funded by National Treasury through the Department of Science, Technology and Innovation, the FuturePHARMA manufacturing facility enables the production of small-molecule active pharmaceutical ingredients using modern manufacturing technologies. This facility will also support process engineering, digital integration and the development of small and medium enterprises within the pharmaceutical sector.

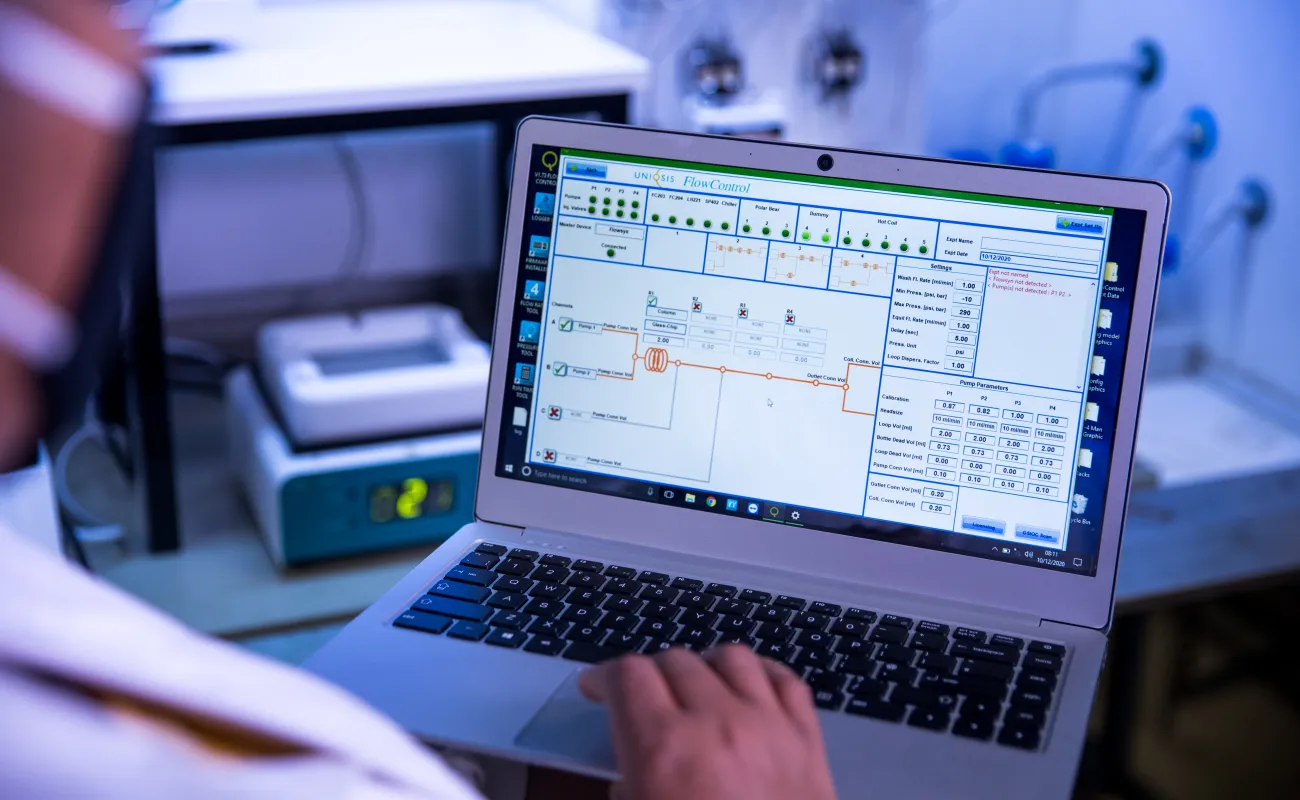

Africa’s first open-access hub for advanced active pharmaceutical ingredient manufacturing

The CSIR has established Africa’s first open-access active pharmaceutical ingredient manufacturing hub that uses continuous flow technology. This is a major milestone in the continent’s efforts to localise pharmaceutical production and strengthen health sovereignty. Watch.

Our capabilities

Our FuturePHARMA (small molecules) facility is designed to provide local pharmaceutical companies and small-to-medium enterprises with access to state-of-the-art infrastructure for developing and producing high-quality active pharmaceutical ingredients, the essential chemical components used in medicines. The research team provides technical support in the development of hybrid batch-flow-biocatalytic processes for the production of active pharmaceutcial ingredients and fine chemicals.

Our facilities