What we do

Contact information:

Highlights

Major metro has a new plan for clean, affordable electricity

The City of Tshwane and the CSIR determined an ideal mix of solar, wind, battery storage, hydro, landfill, and biomass energies as part of a recent study. These renewables could supplement the existing power supply from Eskom to help the city lower electricity prices while meeting growing demand and emissions targets. The study also looked at how embedded generation can boost power security and create export revenues from excess power to the grid. Embedded generation refers to electricity produced close to where it is used and fed into the distribution network. CSIR researchers are urging other municipalities to adopt science-based energy planning and modelling to help reduce emissions, prevent electricity theft, and align with national electricity planning.

Our research

Our capabilities

Our facilities

We support industry through research, testing at our facilities and a range of expert services.

Resources

South Africa’s power generation statistics 2024: A presentation

Go somewhere

South Africa’s power generation statistics 2024: A presentation

Go somewhere

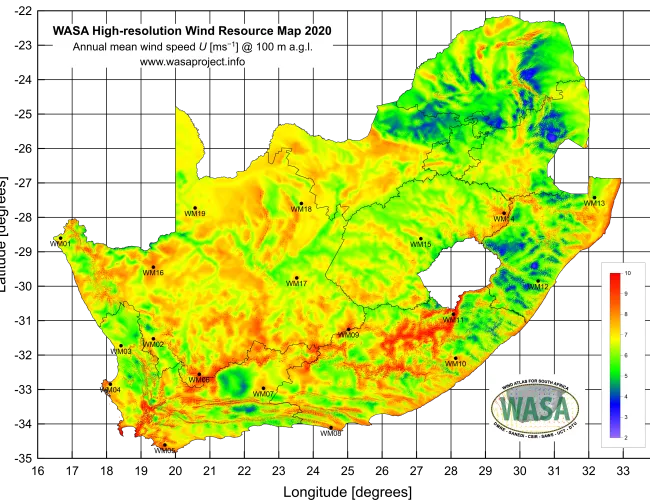

SANEDI Wind Atlas

Go somewhere

SANEDI Wind Atlas

Go somewhere