Highlights

Artificial intelligence used to avoid collisions and improve safety in mines

The CSIR, in collaboration with the Mandela Mining Precinct and the Minerals Council of South Africa, has developed a digital risk assessment tool – the Trackless Mobile Machinery Digital Twin – to help prevent vehicle collisions in mines.

Innovation support and advanced skills for going digital

Mine modernisation entails guiding the sector to adopt fourth industrial revolution (4IR) technologies and digitalisation as enablers of responsible mining practices and operations. A critical component of this transition is the skilling – or reskilling – of a modernised workforce. To support this, the CSIR has established mining learning factories that provide hands-on training through augmented reality, human-computer interaction, co-bots and customised smart systems.

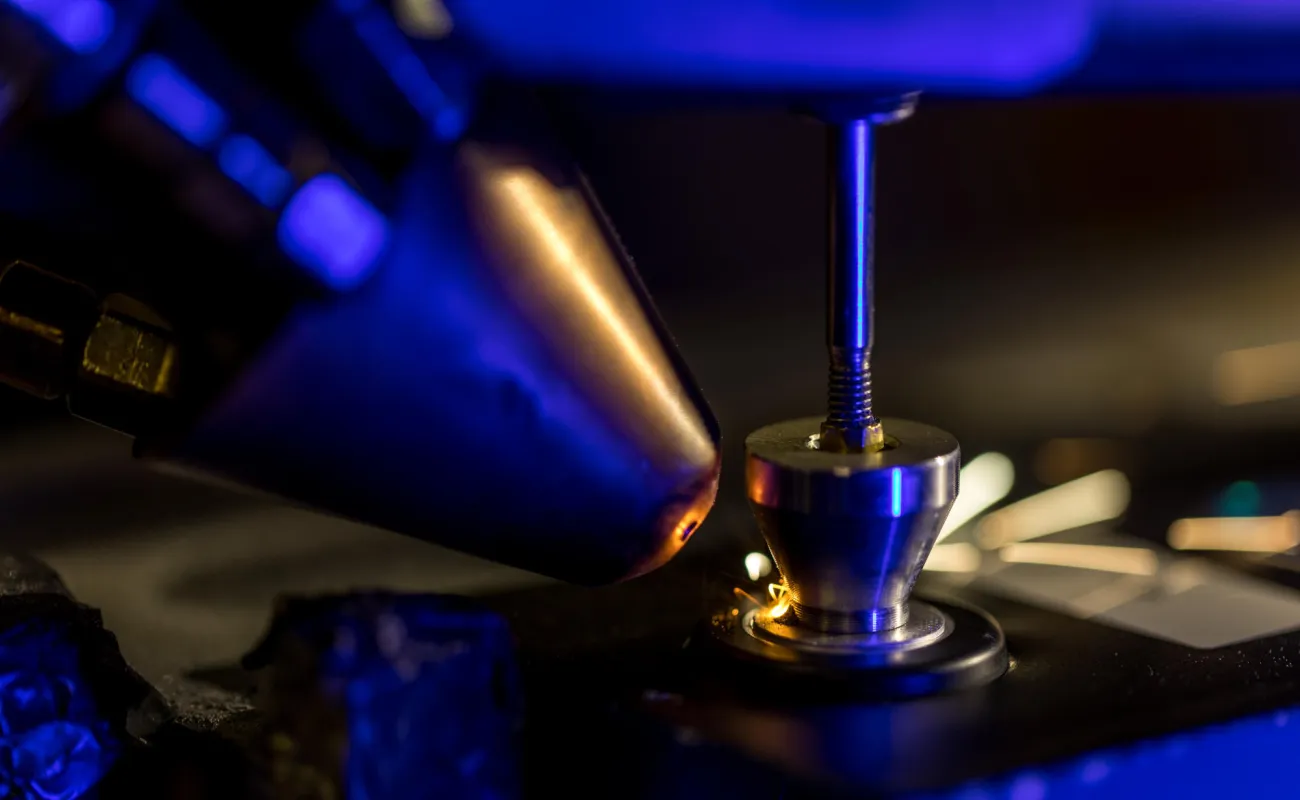

Laser welding gets straight to the point

The heat input of a laser-based welding process is approximately ten times lower compared to conventional welding processes such as tungsten inert gas welding or metal inert gas welding. Since a laser can be focused on a precise spot, it ensures efficient delivery of energy and accurate the laser beam delivery. This results in complex profile weld build-up on existing components, with limited distortion of the component. We design and optimise the laser welding parameters to meet stringent requirements and process qualification. Read More

Understanding suppression of fire for safer underground mobility: A nine-ton flameball

The CSIR conducted a first-of-its-kind fire characterisation test on a full-scale mine locomotive and battery, weighing approximately nine tonnes. In partnership with Sibanye-Stillwater, Trident SA and Mines Rescue Services, the aim was to characterise fire behaviour and identify the most effective suppression methods. A series of large-scale fire exposure tests were carried out on lithium-iron-phosphate battery assemblies, which are increasingly used as a safer, more sustainable alternative to conventional lead-acid batteries for powering underground mining locomotives. The tests, undertaken at the CSIR’s specialised fire and explosion test facility as Kloppersbos, generated data that supports CSIR research on underground fires.

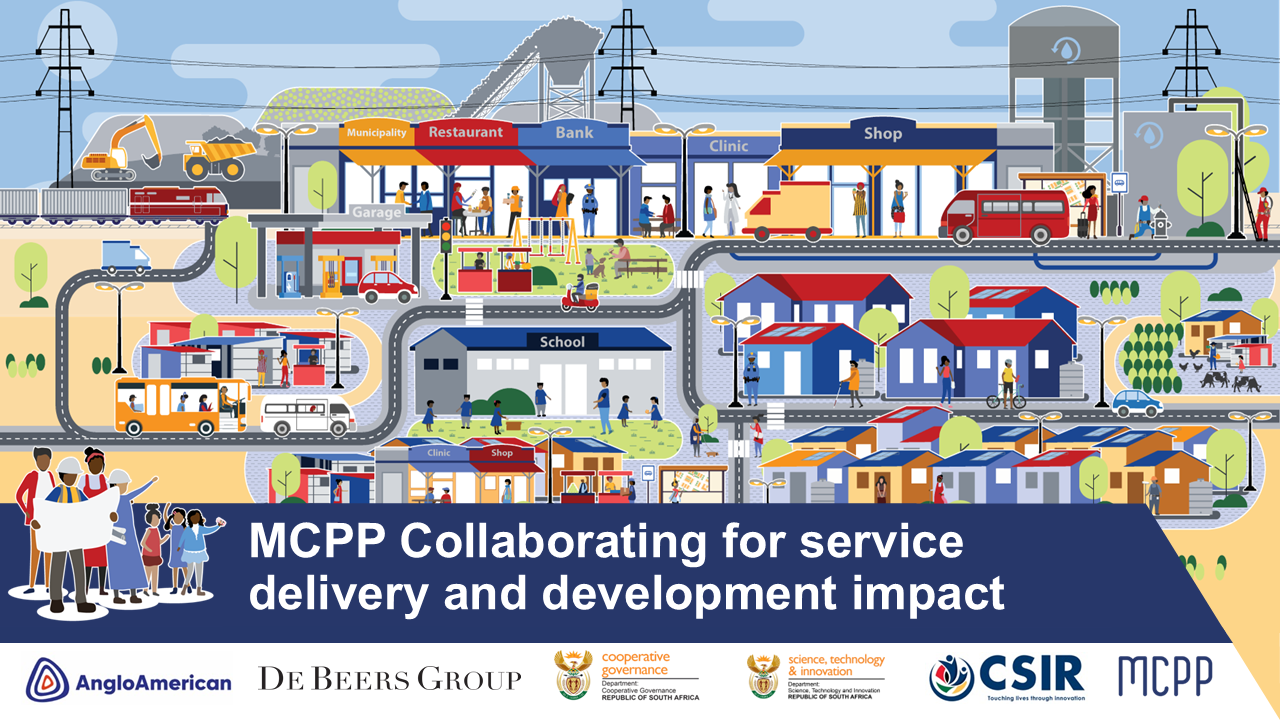

Investment impact and collaboration for postmining futures

TThe MCPP has been working in in 8 mining municipalities in South Africa and the programme results illustrate how partnering can contribute to strengthen municipal service delivery capacity. In the northern-cape iron ore region, the partnership programme has made huge strides in activating partner commitment and collaboration towards creating a post-mining future. Read more.

Our work in mining

We conduct research and development to promote sustainable mining practices. In partnership with industry, we work to revitalise the sector, accelerate its growth and extend the lifespan of mining operations locally and internationally.

Our people:

Our facilities

The CSIR offers a range of specialised, science and technology-based services directly to industry and other sectors. Such services include analytical testing in accredited laboratories, strategic environmental services, wire rope testing, mechanical testing and others. The organisation undertakes these services on a paid-for basis as an independent service provider.