Laser surface modification

Our laser-based engineering solutions are applied in the repair, refurbishment and manufacturing of components and equipment. Novel and specialised, these services typically reduce costs, saving time by limiting downtime, minimising wastage and improving performance.

Contact information:

Highlights

Our capabilities

We have a range of technologies and techniques used in industrial applications. The choice of technology for resurfacing is influenced by warranty stipulations, materials, the nature of the damage, the type of component, the cost of replacement and the urgency of refurbishment.

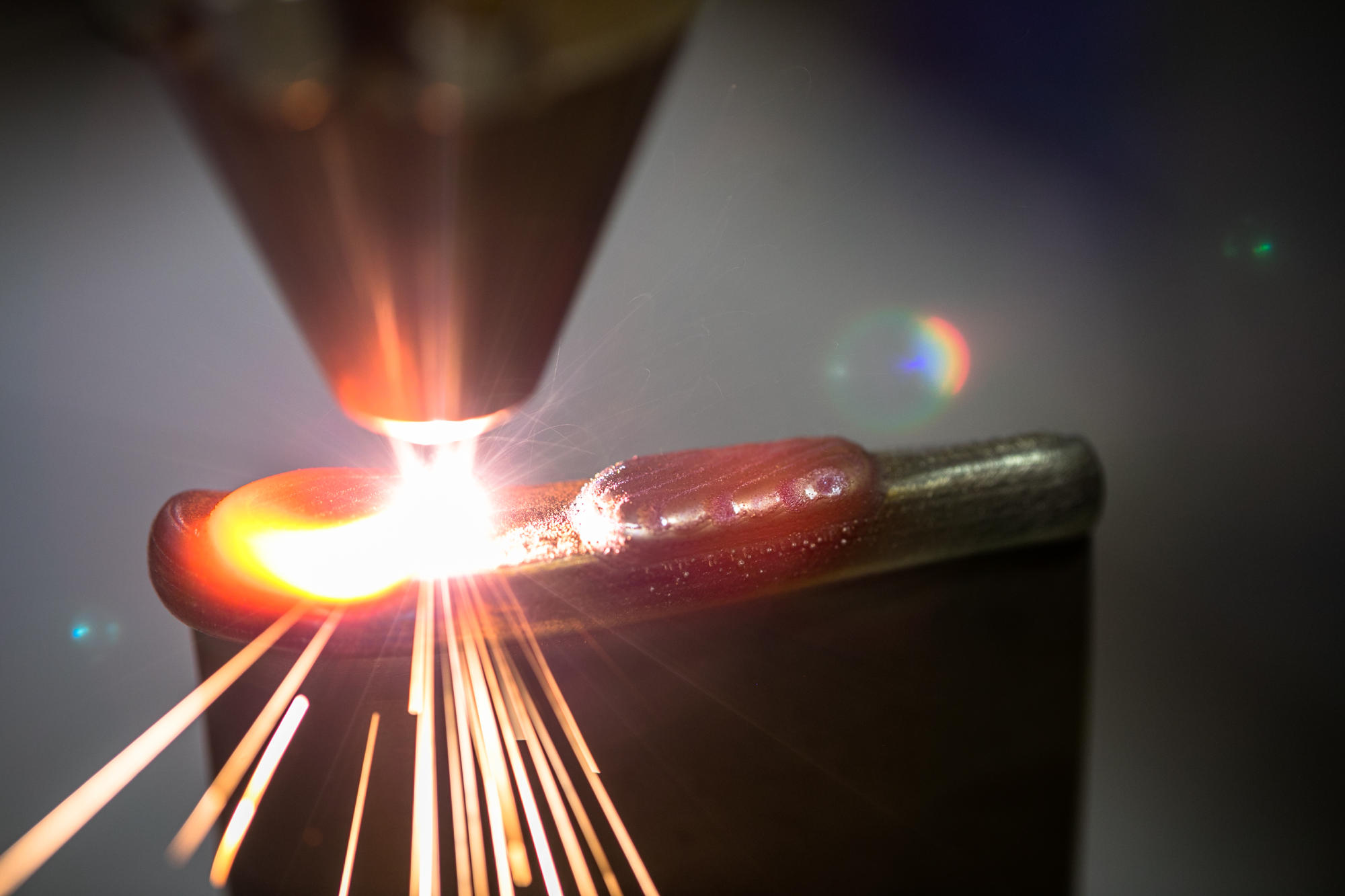

Laser welding

The laser welding process joins components using a laser source, with or without any filler material. This form of refurbishment can be used for automotive body panels, lightweight structures and stainless-steel tubing.

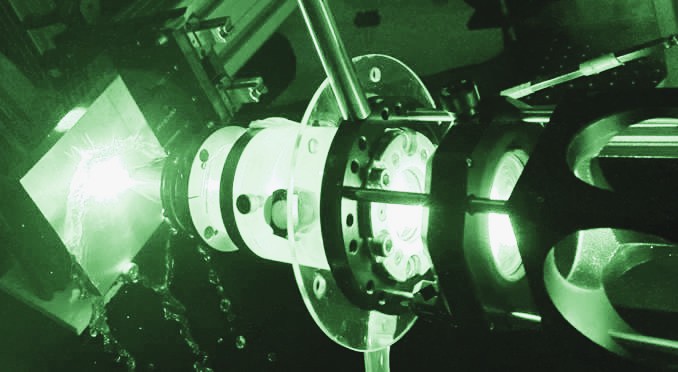

Laser shock peening

This innovative surface treatment induces compressive residual stresses on and beneath the surface through high-magnitude shock waves generated by a high-energy laser pulse. It improves wear characteristics, corrosion resistance and fatigue properties of components. Laser shock peening is applied across a variety of engineering sectors where surface degradation is a major concern.

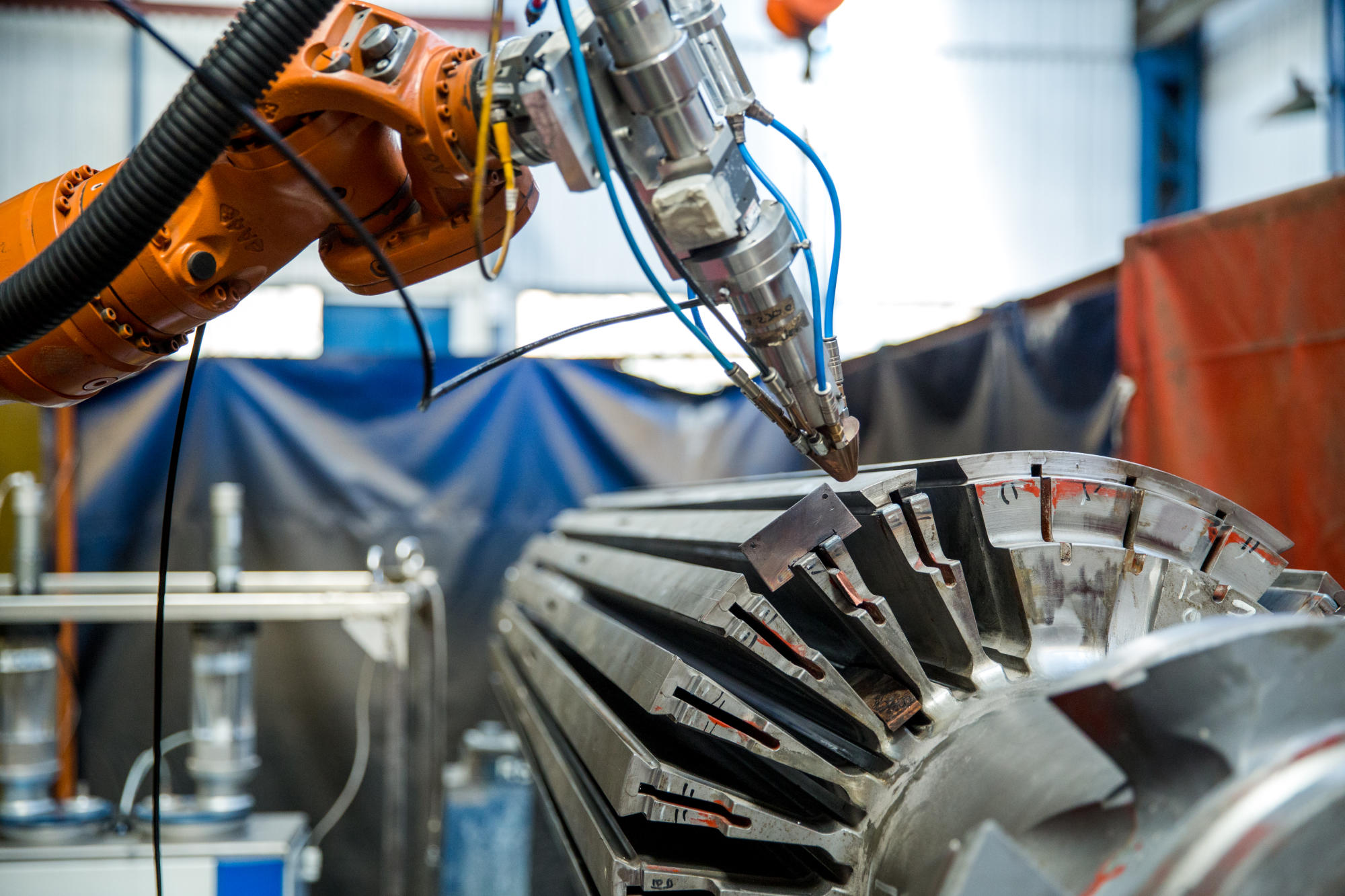

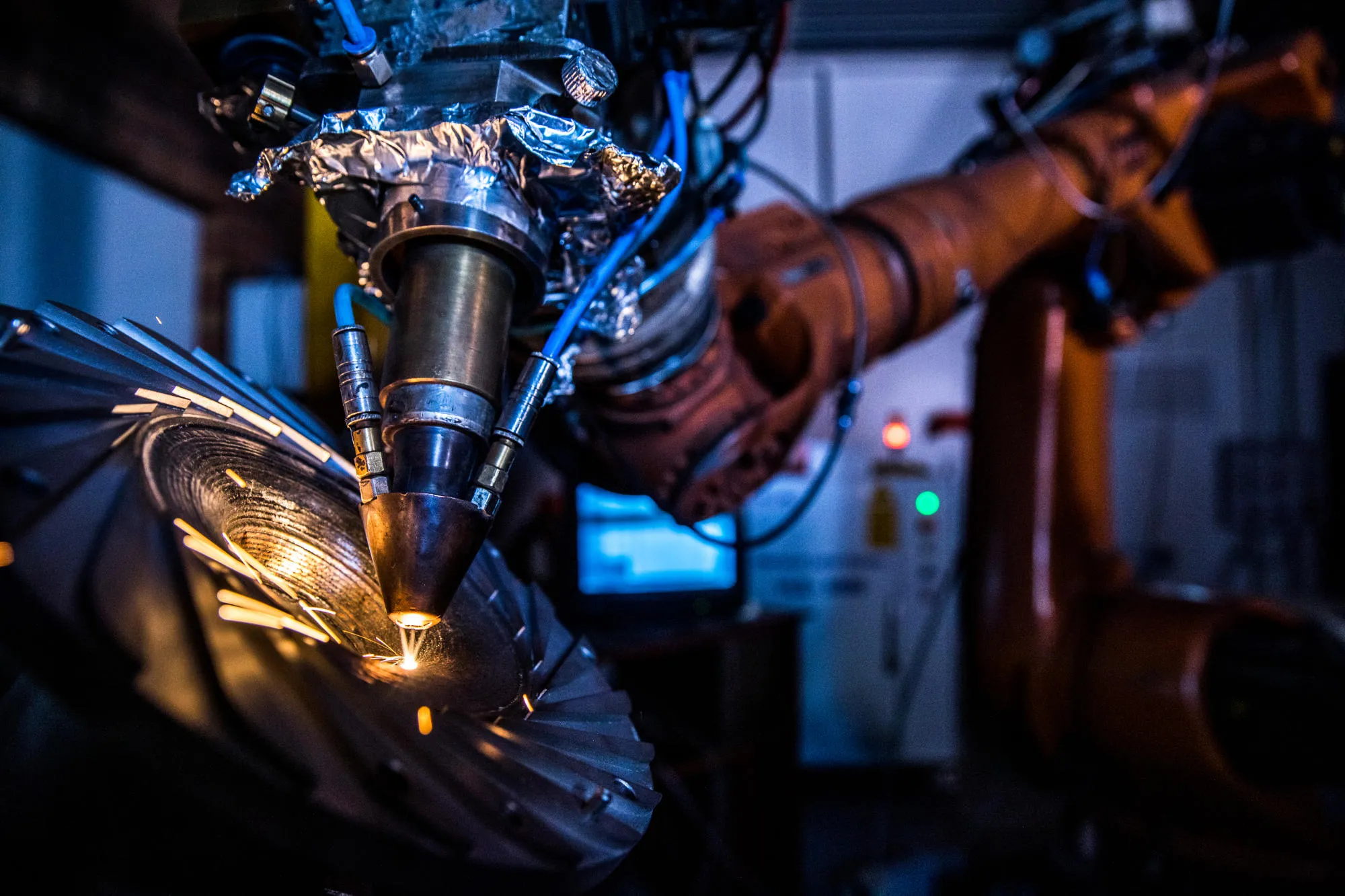

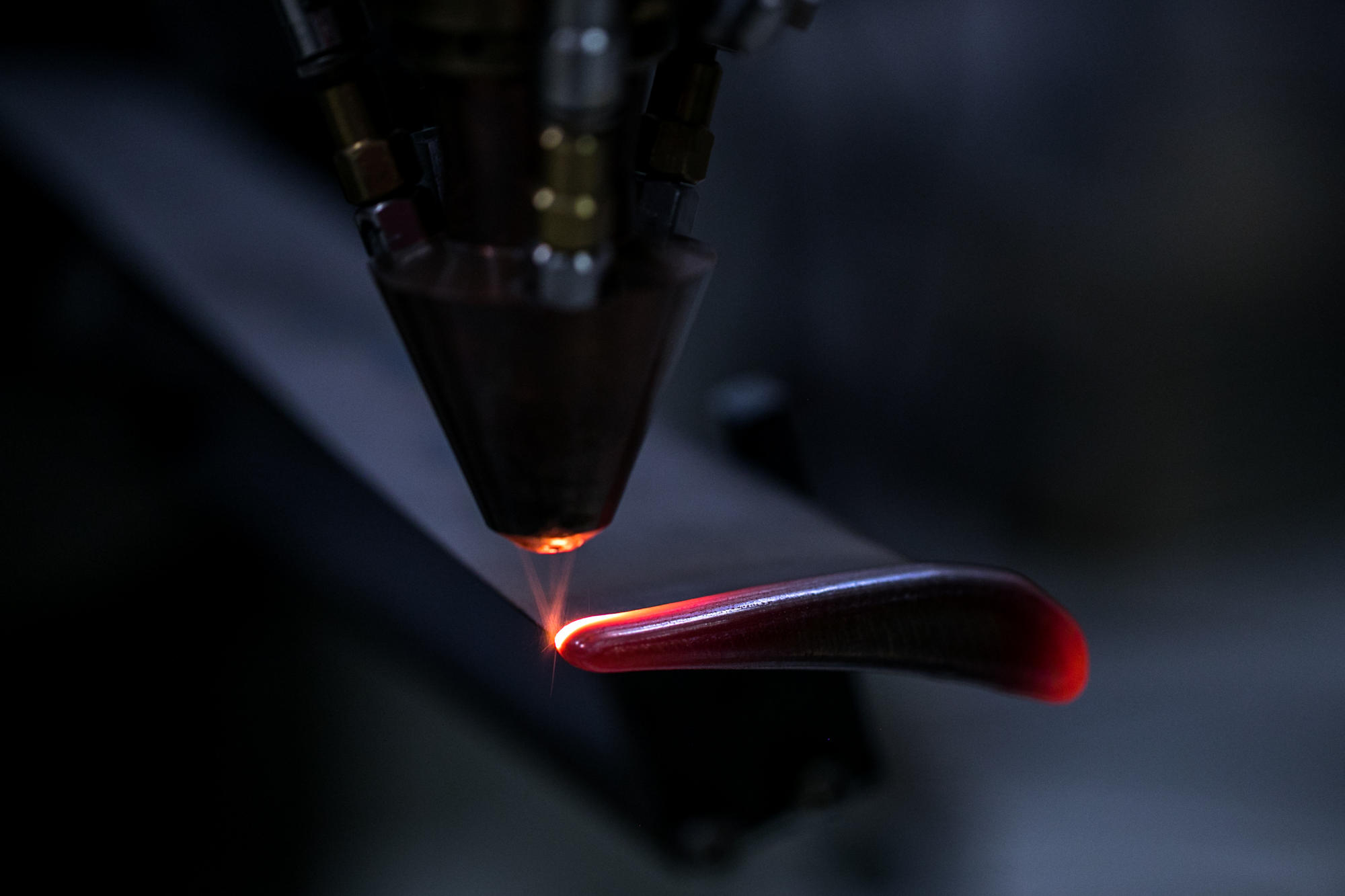

Laser cladding

Laser cladding or welding is fast and accurate, but also expensive. It is a laser weld overlay technique also known as direct energy deposition, direct laser deposition, direct metal deposition, laser hardfacing or laser hardbanding. The process is applicable to the repair of moulds, shafts, turbine blades and press tools.

Our facilities

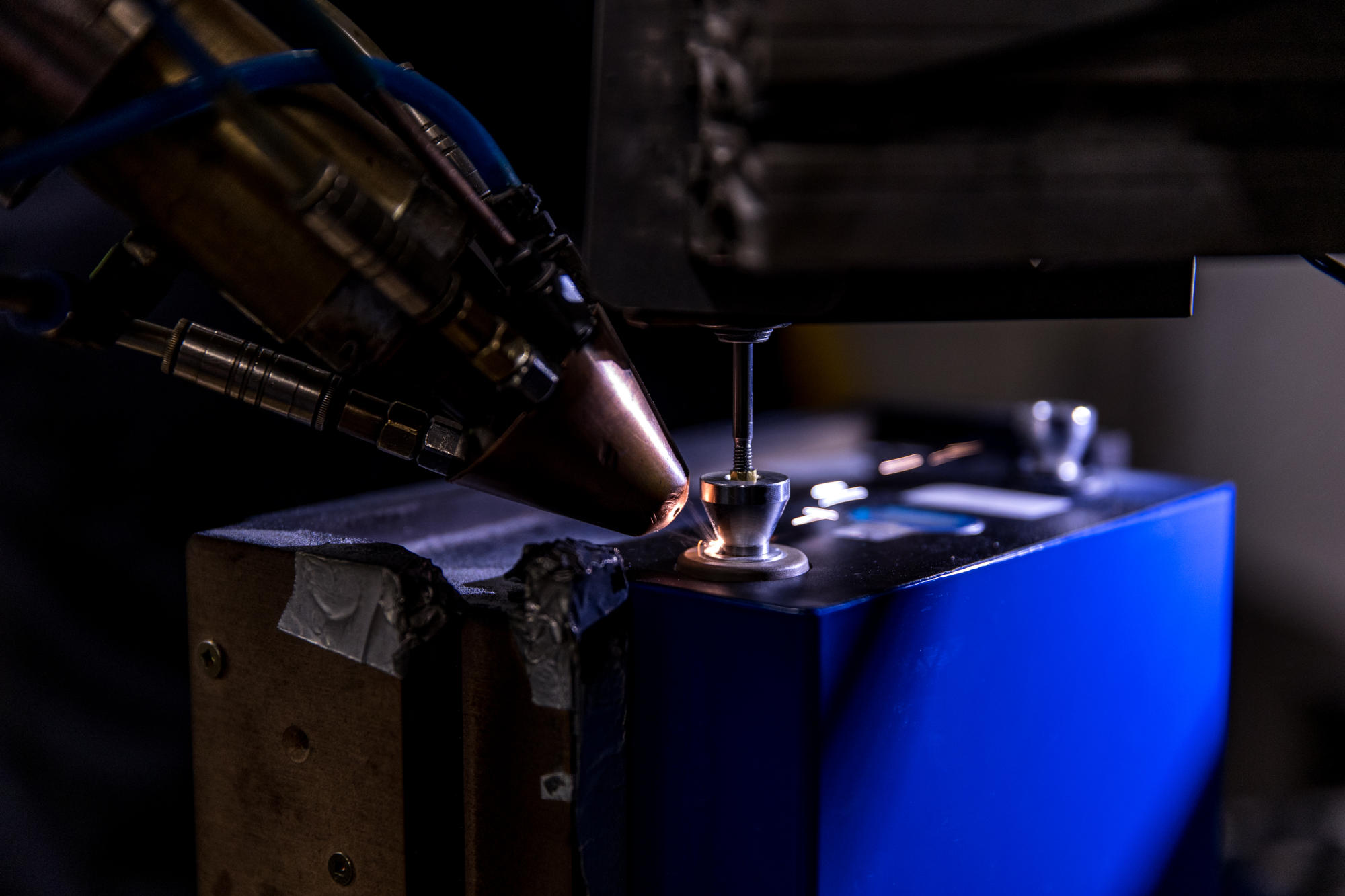

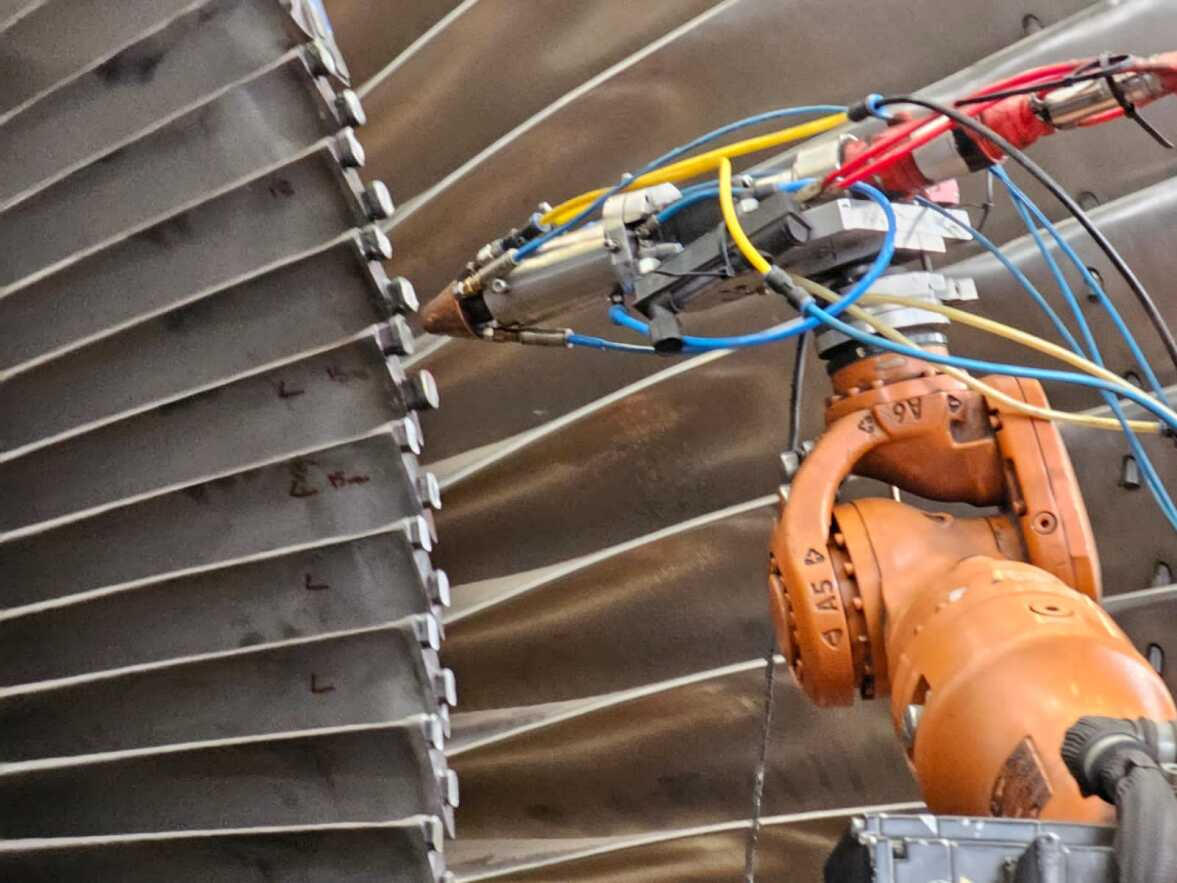

Mobile laser unit

Our mobile facility is designed to support laser-based manufacturing or refurbishment of components at client sites. The unit comprises a high-power laser coupled with a fibre-based delivery system incorporating a laser welding head mounted on a flexible robotic arm that enables accurate and repeatable positioning. The system can be rapidly deployed and is ideal for emergencies or hard-to-transport items.