Advanced casting technologies

We specialise in developing casting techniques such as investment casting, semi-solid metal forming and high-pressure die casting. These processes enable the development of high-temperature alloys suitable for aerospace, automotive, medical and powder generation applications, including lightweighting applications. Castable alloys include aluminum, titanium, steel and magnesium. The hot isostatic press facility is a recent addition and a unique capability for post-processing and heat treatment techniques, offering a valuable service to local industry.

Contact information:

Highlights

Our capabilities

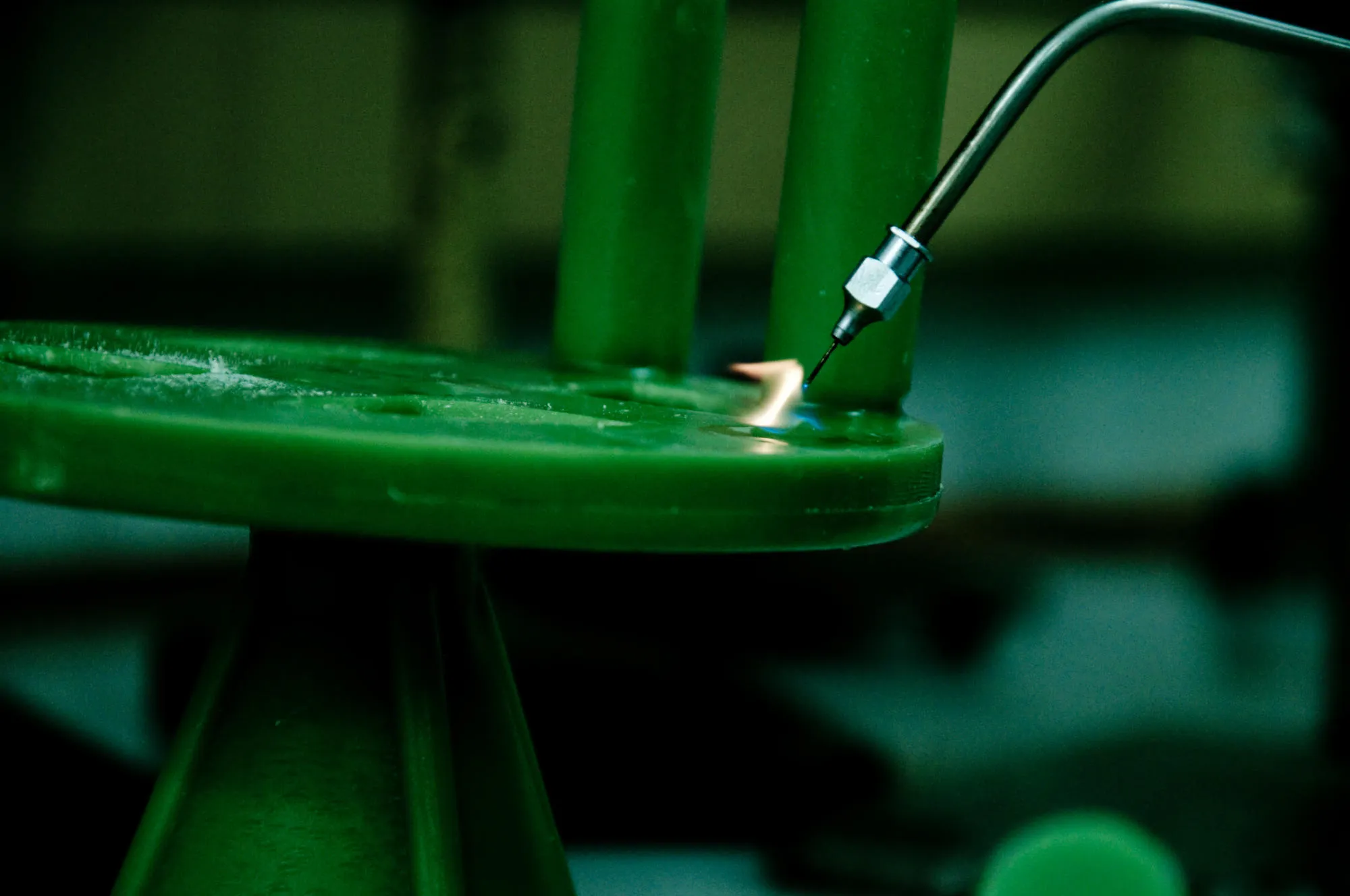

Investment casting

Investment casting is one of our advanced manufacturing capabilities used to produce complex and detailed metal components. The method involves creating a wax model of the desired part, which is then coated in a ceramic material to form a mold. Once the mold is complete, molten metal is poured into it to create precise parts.

High-pressure die casting

High-pressure die casting is a technique used to mould metals. This process involves injecting molten metal into a steel mold under high pressure to rapidly produce parts with dimensional accuracy and smooth finishes.

Vacuum heat treatment

The CSIR also offers vacuum heat treatment, which is essential for enhancing the properties of metals and alloys. This process takes place in a controlled vacuum environment, which prevents contamination and improves the mechanical properties of the materials, such as strength and durability.

Alloy development

Alloy development is a core capability within the CSIR. This involves creating new metal combinations to achieve desired characteristics such as increased strength, corrosion resistance or lighter weight.

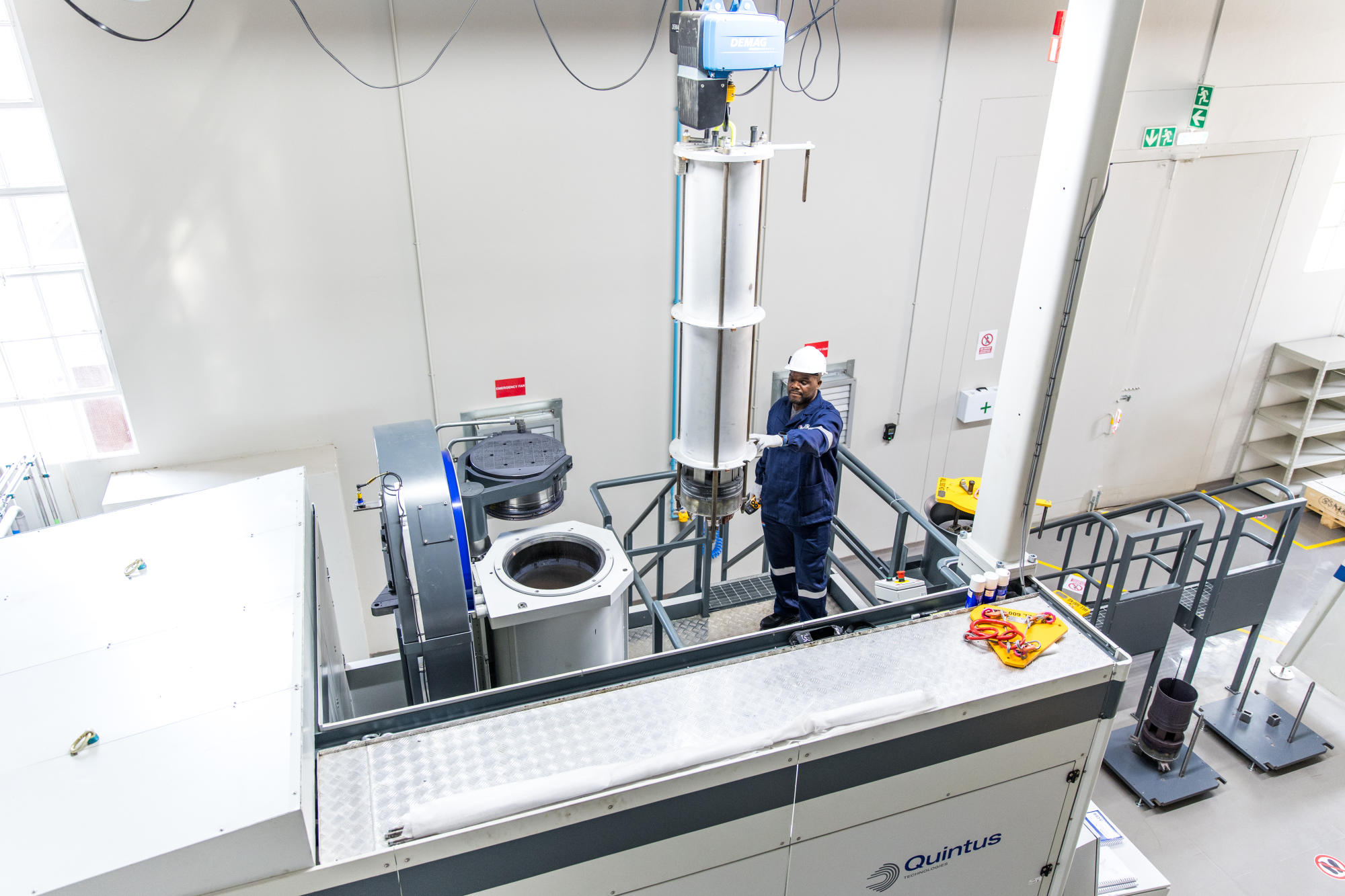

Hot isostatic pressing

Hot isostatic pressing is used for post-processing and testing of parts or materials. It compresses materials at high temperatures and pressures to eliminate internal defects and enhance material properties.

Testing services

A range of testing services is available at the CSIR to ensure the quality and integrity of materials and components. These include non-destructive testing, which inspects materials without causing damage; mechanical testing, which assesses the strength of materials and metallurgical characterisation testing. Together, these capabilities contribute to the development of high-quality materials for various applications.

Our research

Learning Foundry

Our Learning Foundry utilises the ESI ProCAST software. This advanced tool enables more accurate prediction of defects and improved optimisation of processes in the design of moulds and dies.

The Foundry has a structured framework that combines analytics supported by the internet of things and learning driven by simulations. This integration has allowed for enhanced monitoring and analysis of the manufacturing process in real time, leading to more efficient operations and reduced chances of manufacturing errors.

Furthermore, the organisation has incorporated a smart device into non-destructive testing. This device aims to improve quality assurance in foundry operations by allowing thorough inspection without causing damage to materials or products. The combination of these technologies is expected to significantly boost the reliability and quality of products manufactured at the foundry and it aligns with the CSIR's goals of fostering innovation and efficiency in industrial processes.

Our facilities

Investment casting facility

Investment casting is a traditional manufacturing process that uses the lost wax method to produce intricate metal components with minimal machining. Our facility – South Africa's only production-level vacuum casting foundry – advances this process with capabilities in titanium and other alloys, supporting industry through research and development.

Hot isostatic press facility

The hot isostatic press facility has been established to support advanced manufacturing, industrialisation and commercialisation by enhancing the quality and densification of finished metal components. Key processing specifications for selected components include pressure, temperature and weight. The facility serves various advanced and critical applications in the aerospace, medical and defense sectors by ensuring optimal density in processed parts and improving creep and fatigue resistance. View Brochure

Non-destructive testing and metrology facility

We support local industries through non-destructive evaluation and metrology services, including infrared thermographic and ultrasonic testing. Our dedicated laboratory is equipped with X-ray and phased array systems for detecting defects in metal and composite components. The team also conducts structural analysis, corrosion testing and forensic investigations for failure analysis – crucial for quality assurance and risk mitigation across various applications.

Mechanical testing facility

The mechanical testing facility provides high-quality materials testing services to support research and development or industrial needs. The facility is ISO/IEC 17025:2017 accredited, ensuring internationally recognised quality and competence in mechanical testing. Our experts deliver reliable and precise test results. Testing capabilities include accredited tests – such as tensile testing, fatigue testing and fracture toughness testing – and non-accredited tests, including compression testing, hardness testing, three-point bend testing, fracture toughness testing and fracture crack propagation testing.

Metallurgical characterisation facility

The metallurgical characterisation facility analyses the microstructure, properties and chemical composition of materials to understand their behaviour and assess their suitability for various applications. This facility is equipped with techniques such as low-speed cutting machines, mounting machine and grinding/polishing machines for sample preparation; microscopes (light optical microscope, stereo microscope, scanning electron microscope Scanning Electron microscopy/Energy Dispersive X- ray spectroscopy (SEM/EDX)); Vickers hardness testers (micro and macro) for material characterisation, as well as an optical emission spectroscopy for determining chemical compositions of different materials.